|

CONSTRUCTION

|

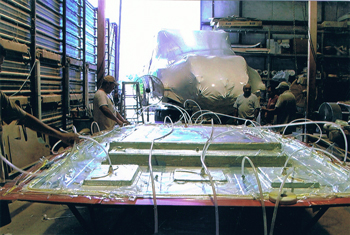

| Deck mold loaded with dry foam core & fiberglass and with vacuum bag & tubing secured, ready for resin to be infused |

|

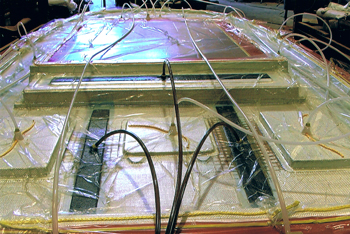

| Resin starting to flow into foam core as evidenced by the darker color of foam around the black fill line anchors |

|

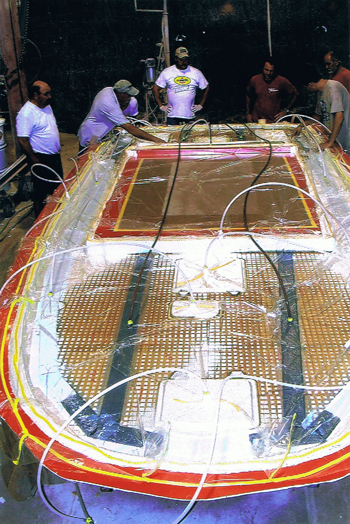

| Deck completely infused with resin, prep time approximately 4 hours, infusion time approximately 30 minutes |

|

| Close-up of hull with fuel line, rigging tube for controls and foam ribs in place |

|

| Ribs, full bulkheads, rigging tube for controls and fuel line all in postion ready for installation of EASI-core flooring |

Lamination and Materials

The RiversEdge 200 FX utilizes premium composite materials and fabrics and 100% of all parts, from the hull to small parts, are laminated using Vacuum Resin Infusion Technology. Not many boat builders can make this claim. The hull materials are 1" foam core, carbon/Kevlar/s-glass and 100% vinyl ester resins. The deck, liner and all small parts utilize 1" core, e-glass and 100% vinyl ester resin. By using these materials and the Vacuum Resin Infusion Technology a boat is produced that is strong, durable and lightweight (dry weight is under 1000 lbs). In fact it is so strong the hull comes with a lifetime warranty against hull punctures. The downside of utilizing Vacuum Resin Infusion Technology is that the process is more expensive not only in materials used but the workers need to be highly skilled. If something goes wrong during the process the part goes to the "scrap heap". The upside to this process is there aren't any "voids", there is consistency of weight from part to part and no VOC's (volatile organic compounds) are released during the molding which makes it a clean and "green" method of lamination. It takes a lot longer to build a boat this way but we feel the end result is well worth what is invested in materials and time. Vacuum Resin Infusion Technology takes boat lamination to the highest level possible.

Exclusive to the RiversEdge 200 FX is the cockpit sole that utilizes EASI-core. The EASI in EASI-core stands for Energy Absorbing Structural I-beam. This flexible flooring system is 1½" resilient urethane foam that has a lot of shock absorbing capacity but is too soft to withstand the rigors of boating by itself, so it is re-enforced by injecting the urethane with vertical "I-beams" of resin to add strength and rigidity. After a day on the water the "give" in the floor will be a welcome relief and will help minimize back, knee and leg fatigue. After the liner is adhered, the cockpit floor is then topped with a layer of Sea Dek foam mat to give even greater cushion underfoot.

The RiversEdge 200FX is fully cored which allows for level floatation (NMMA & USCG compliant) and provides space for over 20 sq. ft. of storage throughout the boat. Because of the coring longitudinal stringers are not used. The structural supports for the cockpit and deck come from five urethane foam ribs and three urethane foam full bulkheads. These structural supports are glued in place using flexible acrylic adhesive. This design concept allows the boat to flex and reacts to wave action more like an airplane therefore giving a "softer" ride.

Assembly

All hardware is 316 grade stainless steel and is mounted with stainless steel fasteners. All the hardware is flush mounted providing 360 degree fish-ability from the 12 inch wide gunwales and over 80 sq. ft. of combined deck area. Cleats, bow and stern eyes are through bolted. Hatch and access lid hinges are drilled and tapped into aluminum backer plates (zero wood is used in the boat). Aluminum backer plates can also be installed as an optional upgrade during construction for any after production accessory. All installed hardware, through hulls and fittings are bedded using UV stable urethane adhesives. Just an extra little step, but what great insurance for secure and rattle free installation.

The one piece ring deck with molded non-skid is joined to the hull via a "shoebox top" fit. The hull to deck joint is securely fastened with both urethane adhesives and stainless steel fasteners. A heavy duty rub rail with vinyl insert completes the hull to deck connection and provides protection against docks and other objects the boat may rub up against.

Rigging

During the assembly process integral oversize PVC hull rigging tubes with pull strings are installed. This assures ease of rigging after the boat has left the factory or if you prefer, as an option, it can be pre-rigged for the engine of your choice.

DESIGN

The RiversEdge 200 FX has been designed to fish the flats and still be able to fish near shore locations. The full tunnel hull allows the boat to draft a mere 7½ inches and can run in as little as 5 inches. With it's 8' beam and LOA of 19'3" it is so stable that it makes walking around the 12" wide gunwales like walking on a dock.

The ergonomically designed oversize center console's 3 inch toe kick allows for ease of movement in the roomy cockpit. Standard height of the console is 50.5 inches at the grab rail. A taller custom height console is available as an option upgrade. On the starboard side of the console, open the hatch and find four integrated tackle drawers. The port side has access to the console wiring, storage space and battery storage. The custom wiring harness utilizes Deutsch DT sealed connectors (the best connectors on the market). Across the top of the console ample space is provided for your own electronics package. A dual battery switch and switch panel with re-set breakers are within easy reach of the helm. Standard gauges are fuel, tach and water pressure along with a flush mounted compass, 2 fire extinguishers and electric horn. The Gemlux tilt stainless steel steering wheel comes with suicide knob. The front of the console has a padded backrest and seat and under the seat is a drop in tub or optional upgrade cooler. The heavy duty, wrap-around windshield and stainless steel grab rail finish off the console.

The roomy 46 sq. ft. self-bailing cockpit has two tunnel transom drains with backflow valves. Under gunwale rod storage can accommodate up to eight 7½ foot rods and the cockpit has red LED courtesy lighting.

Found on the starboard side of the aft deck is the large access hatch to the bilge with automatic bilge pump and single raw water pick-up manifold with shut-off valve. Also found on the aft deck is the transom access plate just in the right place for ease of attaching the jack plate. Standard features are 12" Lenco trim tabs, Atlas or Bob's (your choice) 6" lift jack plate and hydraulic steering. Recessed in the aft deck are the 70 qt. Renewaie circulating bait-well with overflow, light and clear acrylic lid and the 104 qt. Renewaire circulating live-well with overflow, light and solid lid. The clear acrylic lid on the bait-well allows you to see how much bait you have left … no more guessing. The live-well is large enough to easily accommodate "slot" redfish. Live and bait-well tubs are molded fiberglass not the pre-fab drop in liners found in other boats. This is a more expensive way to make the wells but in the long run provide a higher quality product. Bilge, live-well, cast-net and anchor locker hatches are foam cored and molded to insure strength, rigidity and a tight fit and come equipped with stainless steel Gemlux positive tension snap latches. Forward of the bait and live-wells is the combination helm seat with under-seat storage. The hydraulic hinged backrest of the helm seat can be flipped down when fishing to expand the aft deck to over 37 sq. ft. The helm seat is equipped with marine grade vinyl and closed cell foam rubber backrest and seat pads that provide comfortable seating for up to three adults.

Up front under the spacious 44 sq. ft. fore deck is a roomy bow anchor locker, fuel tank with access plate, in-deck cast net locker and two dry storage lockers. The storage lockers are accessed through hatches in the cockpit and have ample space to store up to eight life jackets. An added extra is that the cast net locker is designed to house a five gallon bucket in the molded recess of the floor, so you when you are done with the cast net just open the hatch and drop the net in. No more tripping over gear in the cockpit because of lack of storage. An optional upgrade is to have a forward re-circulating bait-well with light and drain instead of the cast-net locker. The 27 gallon aluminum gas tank was designed to meet 2012 federally mandated fill and vent regulations.

The trailer for the RiversEdge 200FX was customized by Karavan Trailers. It is a single axle aluminum trailer with torsion suspension, 14 inch wheels, an overall length of 21 ft., weight of 536 lb. and has a carrying capacity of 2450 lb. The boat and trailer fully rigged comes in at under 2000 lb. and can be easily pulled by a small SUV.

|